T'Hooft

T'Hooft achieves seamless integration with Technique and Apogee

T'Hooft, a leading independent heatset printer in Belgium, has established a strong reputation in the magazine and advertising segments. To maintain its competitive edge and enhance operational efficiency, T'Hooft integrated the Apogee workflow with the Technique Print MIS system. This strategic move has resulted in a fully automated, streamlined production process, significantly contributing to the company’s profitability and flexibility.

“The synergy between Apogee and Technique unfolds its full potential: all relevant order data, including imposition schedules, are transmitted directly from Technique to Apogee. Before, we had to enter all the data twice—customer name, order number, imposition information, etc.—which was time-consuming and error-prone.”

David Van De Veld, Prepress Manager,

T'Hooft

About the company

Founded in 1949 by Raphaël T'Hooft in the Belgian town of Landegem, T'Hooft has grown from a small print shop into a leading name in the Belgian graphics industry.

Over the decades, the company has remained family-owned and independent, with a strong focus on strategic investments. This commitment to innovation and quality has allowed T'Hooft to become a model in its market.

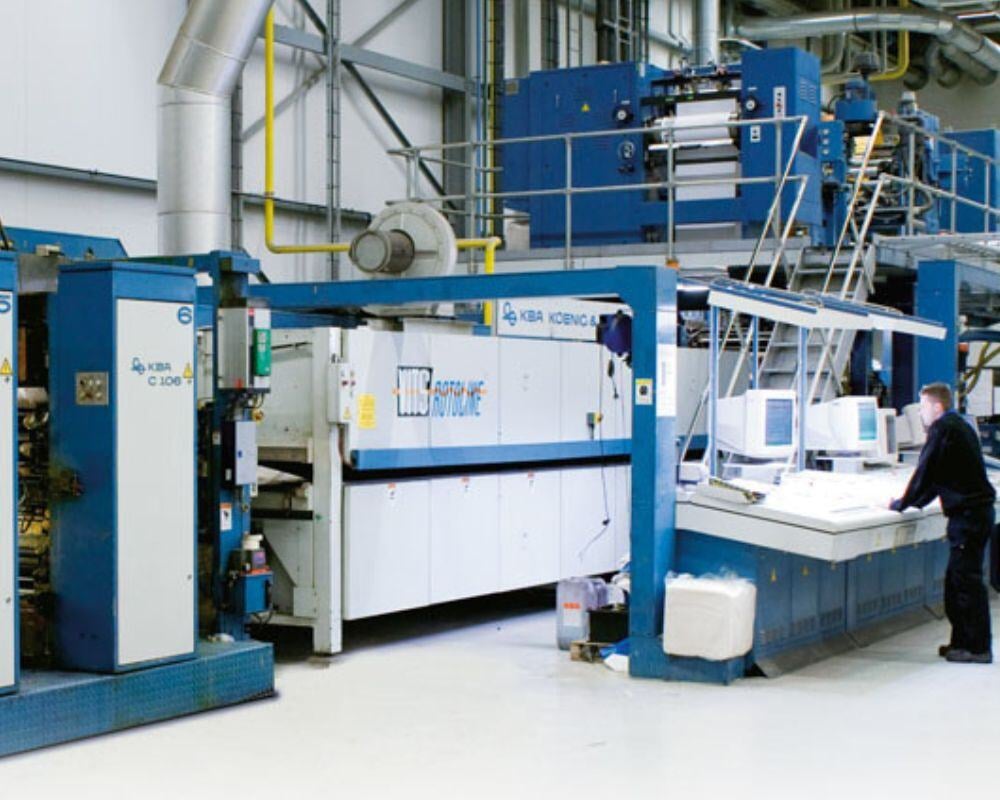

In 2007, the company moved to its current premises in Aalter, where it operates three state-of-the-art presses: a KBA Compacta 818 72-page, a KBA Compacta C80 80-page, and a Lithoman 48-page. These presses, equipped with inline cutting, gluing, stapling, and folding capabilities, enable T'Hooft to deliver high-quality products across a range of formats.

T'Hooft's equipment is designed to handle a wide variety of jobs, from posters and magazines to complex advertising projects. The company serves a diverse customer base, including major retailers across Belgium, France, and the Netherlands. Additionally, the organization shares its premises with two other family-owned companies: the graphic agency Thoverkracht and the mailing and finishing workshop SelectMail. This collaboration allows them to offer an extensive range of services under one roof.

The challenge

T'Hooft has always prioritized innovation and efficiency. Over the years, the company recognized that to stay ahead in the competitive printing industry, it needed to optimize its processes, minimize human intervention, and integrate its systems. However, the challenge was to find a solution that would seamlessly complement their existing Apogee workflow while providing robust management and automation capabilities.

Another challenge for T'Hooft was making sure their operations could scale and meet future demands. As the company grew, they needed a solution that could adapt to new needs. Managing large-scale production while maintaining high quality and meeting deadlines was also a challenge. Integrating new technology had to be done smoothly to avoid disrupting operations, requiring careful planning. Balancing the costs with the expected benefits was also key.

Key requirements

The solution

T'Hooft has consistently led in adopting efficient tools. As an early adopter of the ECO3 Apogee workflow, introduced in 2003 as the first to use the PDF format, the company has benefited from over 20 years of advanced technology. Today, Apogee supports an ECO3 Avalon thermal CtP platesetter, ensuring top performance.

To further improve operations, T'Hooft integrated Apogee with Technique, a leading ERP/MIS solution for the printing industry. After finding another ERP system lacking, they were impressed by Technique’s JDF integration. They installed Technique in 2017, and the integration with Apogee was quickly and effectively implemented. This integration allows T'Hooft to manage job estimates and production scheduling seamlessly, reducing errors and costs. The combined system works efficiently, enhancing overall results.

“Beyond our equipment’s flexibility, our strengths are our responsiveness and speed,” says David Van De Velde, Prepress Manager at T'Hooft. This efficiency is driven by both the commitment of their 40 employees and the effective Technique-Apogee workflow.

A unified system

In practical terms, customer quotations and orders are entered into Technique along with all production data, including imposition. "This is where the synergy between Apogee and Technique unfolds its full potential: all relevant order data, including imposition schedules, are transmitted directly from Technique to Apogee. Before, we had to enter all the data twice—customer name, order number, imposition information, etc.—which was time-consuming and error-prone," explains Van De Velde.

The Impose module within Apogee is one of its strengths. It automatically calculates and updates imposition data according to the parameters of each job, eliminating the need for a vast library of templates. Additionally, the versioning module is highly useful for T'Hooft, as they often print in both French and Dutch for all of Belgium. This integration saves them 15 to 20 minutes per print order.

"Our customers supply the PDF pages online. Technique manages correct customer information, such as customer name and email, and transmits it to Apogee. The customers are then invited via Apogee WebApproval to upload their documents. Proof approval is also completed in WebApproval. If the procedure is followed properly, the job can be printed within 24 hours," adds Van De Velde.

The result

Since integrating Apogee and Technique, T'Hooft has experienced significant improvements in operational efficiency. Automation has streamlined manual processes, reduced errors, and lowered production costs. This has boosted profitability and helped the company stay competitive while maintaining high customer satisfaction.

The smoothness of system upgrades highlights the effectiveness of the integration. David Van de Velde notes, "We recently updated Apogee without any issues with the ERP. When an update is planned, we run tests in advance to identify any potential problems. Keeping all our software up to date is crucial, but the integration saves so much time that it's a major advantage."

T'Hooft’s successful integration of Apogee with Technique sets a benchmark for other printing companies aiming to enhance their efficiency. By investing in automation and seamless system integration, T'Hooft has reinforced its position as a leader in the Belgian graphics industry, proving that strategic investments can drive profitability and customer satisfaction in a competitive market.

-

Significant operational efficiency improvements

Automation reduced manual processes, saving 15-20 minutes per order and cutting costs

-

Enhanced system integration and seamless updates

Seamless data flow and smooth software updates enhanced overall system efficiency

-

Increased competitiveness and customer satisfaction

Streamlined operations allowed jobs to be printed within 24 hours, boosting customer satisfaction

-

Reduced error rates

Automation minimized human errors, improving accuracy and quality

-

Time savings and improved productivity

Automated imposition and versioning increased productivity and optimized workflow

“Our customers supply the PDF pages online. Technique manages correct customer information, such as customer name and email, and transmits it to Apogee. The customers are then invited via Apogee WebApproval to upload their documents. Proof approval is also completed in WebApproval. If the procedure is followed properly, the job can be printed within 24 hours.”

David Van De Veld, Prepress Manager,

T'Hooft